Be sure all connections are secure, and attaching surface is clean 3. Allow welder to cool until ON/OFF Switch lamp goes out 2. Wire Feed Arc Welder For Information About This Product, Call 1-80 Troubleshooting Chart - Welder Symptom Possible Cause(s) Corrective Action No output 1. This is called backhand or pull technique (See Figure 14). For thicker steel, the nozzle should point into the puddle to increase weld penetration. For thin materials (18 gauge and up) and all aluminum, the nozzle should point out in front of the weld puddle and push the puddle across the workpiece. WG3013 Welding Guidelines (Continued) PUSH VS PULL TECHNIQUE The type and thickness of the work piece dictates which way to point the gun nozzle. SLAG REMOVAL (FLUX-CORE WIRE ONLY) Wear ANSI approved safety glasses (ANSI Standard Z87. For aluminum, travel speed is typically faster. When the speed is too slow, the weld metal piles up and the bead is high and wide. When the speed is too fast, the bead is narrow and bead ripples are pointed as shown. Wire Feed Arc Welder Welding Guidelines (Continued) work piece material thickness all affect the speed of travel necessary for completing a good weld (See Fig. The flux creates a shielding gas when melted. The gasless process uses a tubular wire with a flux material inside. The weld must be protected (shielded) from contaminates in the air while it is molten. WG3013 Welding Guidelines General Nozzle Contact Tip Shielding Gas Flux (Gasless only) Slag Weld Wire Crater Work Piece Figure 9 - Weld Components This line of welding machines can utilize the Flux Cored Arc Welding (Gasless) process or the Gas Metal Arc Welding (MIG) process. Plug the input cord into a proper voltage receptacle with proper circuit capacity (See Chart under circuit requirements on page 1). Rotate the Wire Speed Control to setting number 5 to start with, then adjust as needed after test weld. Heat setting may vary according to welding conditions and materials. NOTE: These settings are general guidelines only. Wire Feed Arc Welder Operation (Continued) See application decal inside door of wire feed compartment for proper heat settings. Lens Lens Retainer Retainer Stiffener Figure 6 4. Attach the stiffeners over the pins on the lens retainers (See Figure 6). Trim the excess plastic to remove sharp edges.

Cut retainer stiffeners and detachable handle away from shield. Handshield Assembly NOTE: Shielding gas is not required if flux-cored welding wire is used. Welding operations may continue when the yellow lamp is no longer illuminated. WG3013 Assembly (Continued) if the duty cycle is exceeded. Fasten screws through bracket and into cabinet. Place bracket on welder aligning the holes in welder housing. Secure wheel with e-clips and wheel caps. Insert axle through the axle supports and firmly push wheels onto axle. Insert axle supports into slots in the welder housing. Fasten screws through top cover and into handle. Wire Feed Arc Welder Assembly (Continued) and top cover aligning the holes in handle with holes in top cover. Do not perform electric arc welding operations on metals that are galvanized or cadmium plated, or contain zinc, mercury, or beryllium without completing the following precautions: a.Keep the head and face out of the welding fumes.If the welding area cannot be adequately ventilated, be sure to use an air supplied respirator. WG3013 General Safety (Continued) ! WARNING Do not breathe fumes that are produced by the arc welding operation. Failure to follow safety precautions or instructions can cause equipment damage and/or serious personal injury or death. Before starting or servicing any electric arc welder, read and understand all instructions.! WARNING ! WARNING Always keep a fire extinguisher accessible while performing arc welding operations. Wire Feed Arc Welder General Safety (Continued) Torch is “live” (has current potential) at all times when machine is turned on. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference. Protect yourself and others by observing all safety information. Read carefully before attempting to assemble, install, operate or maintain the product described.

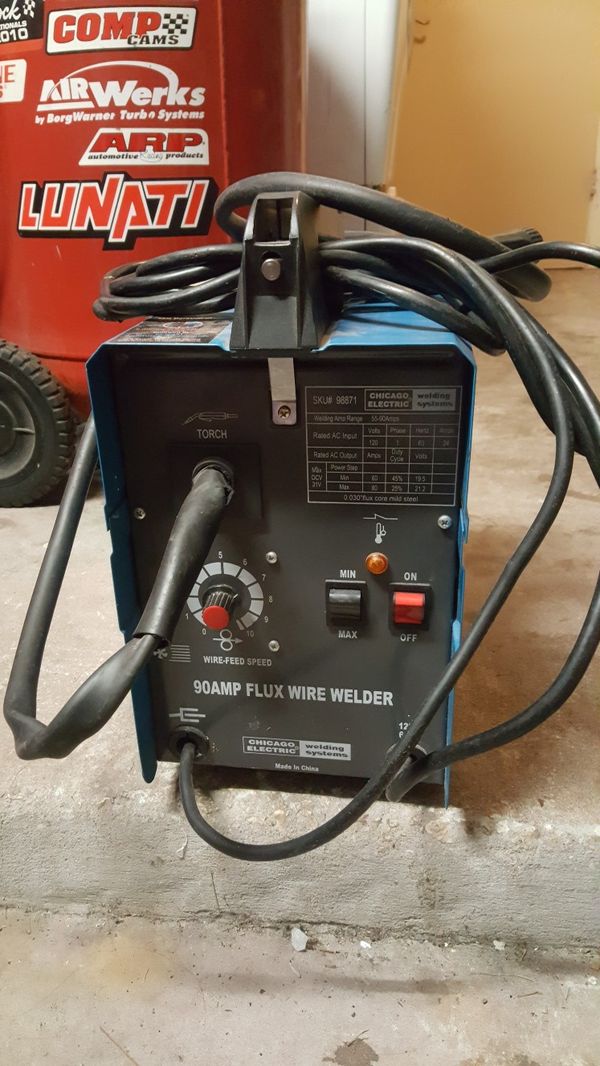

Campbell hausfeld welder flux core 80 parts manual#

Model WG3013 Operating Instructions & Parts Manual Please read and save these instructions.

0 kommentar(er)

0 kommentar(er)